Founded in 1845, William Blythe has pioneered the development and application of inorganic chemistry for demanding applications for more than 180 years. Our products are used across the pharmaceutical, polymers, electronics, catalysts and renewable energy markets.

We use industry-leading manufacturing technology combined with world-class chemistry R&D and analytical capabilities.

William Blythe is one of the oldest inorganic chemical manufacturers in the UK. The core of our current chemistry is based around copper, tin and iodine compounds. Originally, the business manufactured chemicals for the local textile industry, since then the company has transformed itself and its products numerous times. This culture of adaptability and continual innovation remains core to the business philosophy to this day.

We have world class research facilities and a team of highly skilled scientists ready to provide inorganic material solutions for the challenges of tomorrow. We have a strong track record of taking new innovations from lab scale to industrial manufacturing.

Markets

![]()

Flame Retardants

FLAMTARD

Antimony-Free Flame Retardants

William Blythe is a global leader in the manufacture of antimony-free, flame retardant synergists for polymers under our brand: Flamtard™.

Based on zinc, tin and mixed metal oxide technology (eg. zinc hydroxystannate and zinc stannate) the Flamtard™ products are synergists that offer flame retardant and smoke suppressant properties in a range of polymer systems, including PVC, polyamides, elastomers and thermosets. The Flamtard products are commonly used to replace ATO (antimony trioxide) in polymer applications such as wire and cables, roofing membranes and artificial leather.

Heat Stabilisers

Potassium and Copper Iodide for Engineering Polymers

We manufacture highly specified potassium iodide and copper iodide for use as a heat stabilising combination for polyamide 6 and polyamide 6,6 plastics.

Copper iodide and potassium iodide are a synergistic stabilisation package used at low loadings to prevent thermal oxidation of polyamide compounds. Upon exposure to high temperatures, hydroperoxide groups are generated which can cause polymer chain breakage if converted into a free radical. The reducing nature of iodide ions and the catalytic effect of copper work to decompose these hydroperoxide groups, avoiding the generation of free radicals. This ensures long-term stability of polyamide compounds for automotive applications.

Purification Absorbents inc DURAGUARD

Sulfur and Mercury Removal

William Blythe offers fixed-bed absorbent products for sulfur and mercury removal in natural gas processing plants under the DURAGUARDTM product family.

DURAGUARD™ absorbents have high capacity, long-life and are a cost-effective solution for gas & liquid gas streams. All DURAGUARD™ products come with a full lifecycle support package from a team with 50+ years’ experience in gas processing.

Catalysts

Inorganic Catalysts for Polymers and Oleochemicals

We manufacture compounds based on tin and graphene oxide that have uses as catalysts.

Thermoplastic Vulcanizate Crosslinking

Thermoplastic Vulcanizates (TPV) are high performance polymers that offer the benefits of thermoplastic processing whilst retaining the elasticity of rubber. We offer anhydrous tin chloride as a resol crosslinking co-catalyst in the manufacture of TPVs.

Pharmaceutical

Copper, Iodine and Tin Compounds for Pharmaceutical Manufacturing

We supply high-quality products based on copper, tin and iodine, into the pharmaceutical industry that can act as catalysts, oxidizing agents or reducing agents in the production of active pharmaceutical ingredients (API).

Electronics

High-Purity Tin and Iodine Derivatives

We manufacture a range of tin and iodine compounds to very low levels of impurities for the electronics industry.

Energy Storage and Harvesting

Advanced Materials for Sustainable Technologies

We are developing a range of products across battery technology, energy harvesting and energy conservation applications, using in-house expertise in inorganic precipitation chemistry

Metal Plating

High-Purity Tin Derivatives for Metal Plating

Tinplate

We manufacture high-purity tin dichloride that is used as a source of Sn(II) for the electroplating of steel in high speed continuous production lines. Tin provides surface protection as a corrosion inhibitor and is also used for decorative purposes.

Electronics

High-purity tin dichloride is used for plating tin-nickel alloy and in sensitising solutions for plastic metallisation in the manufacture of printed circuit boards (PCBs). Tin monoxide can also be used to manufacture high-purity tin salts for use in high-speed electroplating, such as tin methansulfonic acid.

Pigments

Tin-Based Pigment Precursors

Tin Monoxide

Tin monoxide is a key component in complex inorganic oxide pigments, for example rutile tin zinc (RTZ) orange and yellow pigments. An optimised particle size and surface chemistry are core to product performance in the manufacture of inorganic pigments.

Tin Dichloride

Tin dichloride a source of tin for the manufacture of pearlescent effect pigments.

Food & Feed

Iodine Derivatives for Food and Feed

Iodine Supplements

Potassium iodide and potassium iodate are used as food supplements to counter iodine deficiency in humans and animals. Iodine is essential for good health and is needed for effective thyroid gland operation, which affects the body’s metabolic and immunity functions.

Process Chemicals

High-Quality Inorganic Compounds for the Chemical Industry

We manufacture tin, iodine and magnesium based compounds that are used in a range of industrial processes. Key to all of these is providing market leading quality and service.

Printing Chemicals

Periodic acid and sodium periodate are used as oxidising agents in silk screen printing. The periodate ions selectively decompose cured emulsions that are used as printing stencils, which are then removed from the delicate silk screen. The silk screen is then reclaimed and can be reused in the process. High purity magnesium nitrate solutions can be formulated into Fountain Solutions for the printing industry. This provides corrosion resistance prolonging the lifetime of the printing plate

Mirror Solution

Tin dichloride is used as a reducing agent in the production of mirrors. During the silvering process of mirrors, tin (II) chloride is used to reduce silver and improves the adhesion of the silver to the glass surface.

Oil & Gas

Tin dichloride is used in oil & gas applications as a reducing agent for iron in oil wells. Insoluble ferric iron compounds are a key factor in the generation of sludge in acidizing treatments. The addition of tin dichloride to the acidizing solution ensures that iron remains in the ferrous state and prevents the formation of sludge. Potassium iodide and copper iodide can also be used as corrosion inhibitors in oil well drilling.

Manufacturing

We have developed a vast amount of experience and knowledge in the production of inorganic materials. Underpinning everything we do is operation at the highest standards of quality control. This runs through both product, quality performance and service that we offer our customers. Our core capability is the manufacture of rigorously defined, high purity functional inorganic chemicals. This is achieved through a range of chemical processing routes including bi-tri metallic precipitation, redox chemistry and hydrothermal synthesis. Once the target chemical is manufactured, we have a toolkit of purification techniques that we can employ to produce high purities to specification. We also utilise post processing techniques such as blending, granulation and masterbatch production.

Chemical Development

Our R&D team have extensive knowledge of bi-metallic and tri-metallic precipitation reactions, continuous flow reactors, hydrothermal synthesis, redox chemistry, electrochemistry, calcination and purification. We’ve worked with blue-chips, start-ups and academia in developing scalable manufacturing routes to new inorganic materials.

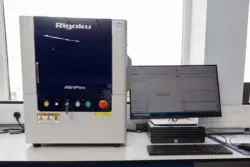

Characterisation

Control of the physical and chemical properties of inorganic chemicals is our core capability. We have a suite of materials characterisation techniques to ensure product quality throughout scale up including SEM, XRD, XRF, ICP-OES, TGA/DSC, surface area, particle size and metal assay.

Process Scale up

When working on innovation projects for customers, we can take new process routes from gram to kilo to hundreds of kilogram quantities in our R&D laboratories. In 2022 we installed a new scale-up facility designed to take new processes to industrially relevant reactors, allowing us to supply new materials at 100’s kg quantities for pilot scale processes.

Pilot Manufacturing

It is crucial to have flexible pilot scale manufacturing assets to transfer lab processes and demonstrate scalability. Our R&D team work hand in hand with our chemical engineers and analytical chemists to ensure that new processes are effectively and safely transferred to pilot scale manufacturing.

Application Testing

We have capabilities for lab scale testing across a range of industries including polymer processing, fire testing, gas absorbent capacity and batteries.

Technologies For Tomorrow

We have developed functional materials that enable many new advanced technologies some examples are below ;

Graphene Oxide

Near Infrared Absorbers

Flame Retardant Systems including the following attributes covering the Flamtard range ;

-

Antimony trioxide (ATO) replacement

-

Antimony trioxide (ATO) alternative

-

Zinc hydroxystannate (ZHS)

-

Zinc Stannate (ZS)

-

Antimony Free

-

ATO free

-

Non-hazardous

-

Flame retardant synergist

Perovskite Precursors for PV

Thermo-electrics

Purification Absorbents

Catalysts

Energy Storage Materials

Products

– Advanced Materials

– Flame Retardants

– Iodine

– Process Chemicals

– Purification Absorbents

– Tin

View All Products Here

Quality Control

We aim to ensure the highest levels of quality in everything we do. Our Quality Management System is ISO 9001 accredited and our team strives to exceed customer expectations in quality control and customer service. Our quality control laboratory is equipped with advanced analytical techniques, enabling us to characterise the chemical and physical properties of every batch manufactured at William Blythe.

Bespoke & Custom Product

Bespoke Product Manufacturing

Our multi-purpose production facility can also be employed to offer greater synthetic flexibility where smaller volumes of material are required. If your current requirements are not met by the products on our product pages, please do get in touch. Our team is keen to tackle any challenge you may have.

Message William Blythe Ltd directly.

Kevin Hudson, Jonathan Hall, Thomas Tang (Asia), Seb Grizard (EMEA), Cameron Day (Americas)