Polymer Systems Technology Limited was established in 1994, and is located in High Wycombe, approximately 25 miles west of London. The company has grown progressively since then, moving to newly built premises consisting of 6,000 square feet in 2005. A recent expansion has seen the premises increase to 12,000 square feet in 2016 and then to 18000 sq feet in 2018.

PST is a company committed to meeting the agreed requirements of our customers, both internal and external, on time, every time, and to be a diligent supplier of polymers without detrimental harm to the environment.

Biomaterials include

- Liquid Silicone Rubbers

- High Consistency Rubber

- Adhesives

- Gels

- Primers

- Low Viscosity Elastomers

- Dispersions

- Foam

- Inks & Masterbatches

- Lubricious Coatings

- Liquid Silicone Rubbers

- High Consistency Rubber

- Adhesives

- Gels

- Primers

- Low Viscosity Elastomers

- Dispersions

- Foam

- Inks & Masterbatches

- Lubricious Coatings

- Electrically Thermally Conductive

- High Consistency Rubbers

- Liquid Silicone Rubbers

Advanced Technologies include

- Adhesives & sealants

- Thermally conductive materials

- Tapes film adhesives PSAs

- Foams

- Gels

- Grease & dampening fluids & lubricants

- Primers

- Electrically conductive & static dissipative

- Coatings

- Adhesives

- Electrically conductive & static dissipative

- Thermally conductive materials

- Gels

- Fluorosilicones

- Foam

- Primers

- Moulding materials

- Paints & coatings

- Adhesives

- Electrically conductive & static dissipative

- Thermally conductive materials

- Gels

- Fluorosilicones

- Foam

- Primers

- Moulding materials

- Paints & coatings

- Potting & encapsulating gels

- Primers

- Potting & encapsulating elastomers

- Coatings

- Adhesives

- Electrically conductive & static dissipative

- EPM Electronic Packaging Materia

- Thermally conductive

- Fluorosilicones

- Potting & encapsulating gels

- Primers

- Potting & encapsulating elastomers

- Coatings

- Adhesives

- Electrically conductive & static dissipative

- EPM Electronic Packaging Materia

- Thermally conductive

- Fluorosilicones

Other

VeraSil 30, 40, 50, 60, 70 & 80 durometers

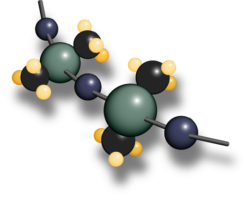

A family of versatile high consistency elastomers designed for optimal performance in a wide range of applications. This 3 part system includes 6 base stocks which when vulcanized produce tough, durable elastomers with nominal Shore A durometers of 30, 40, 50, 60, 70 and 80. Additionally, the base stocks may be blended to produce elastomers of intermediate durometer. The 6 base stocks were developed to be compounded with CAT‑40 and CAT‑55. CAT‑40 is the inhibitor component. CAT‑55 is the platinum catalyst component. This allows the customer to adjust work time and cure schedules, which the two Part systems do not allow.

Find a silicone solution

How far will you go to find a silicone solution to a problem or explore a disruptive technology to take your business to a level way above the competition?

Polymer Systems’ library of silicone materials are looking for a problem to solve. Fresh eyes focusing on an old problem trending now prevalently in the emerging disruptive science of battery technology…

See more…

Quality Statement:

-

- Polymer Systems Technology Limited was established in 1994, and is located in High Wycombe, approximately 25 miles west of London. The company has grown progressively since then, moving to newly built premises consisting of 6,000 square feet in 2005. A recent expansion has seen the premises increase to 12,000 square feet in 2016 and then to 18000 sq feet in 2018.

- PST is a company committed to meeting the agreed requirements of our customers, both internal and external, on time, every time, and to be a diligent supplier of polymers without detrimental harm to the environment.

- Product quality and safety in use are of paramount concern to us. It is for this reason that registration to the approved quality standards was sought. Accreditation was first achieved in 1997, and we are proud to announce that we now hold the latest revision, ISO.9001:2015. As a logical and essential development of our ongoing commitments we sought and achieved registration to the environmental standard ISO:14001 in 2002.

- Our ISO systems control every aspect of the product from the moment it arrives at our premises right through to delivery to our customers.

- Included in the cost of the product are Material Certifications, these detail the results of the testing carried out on each individual batch. Customers purchasing our materials also have access to FDA masterfiles. We do not charge additional fees for this service.

- Customers are welcome to use our onsite laboratory where they can get hands on with the materials, and receive expert help and advice from our dedicated team. We can also offer your company training sessions or seminars.

All our machines are CE marked where required and we are working with our manufacturing partners to ensure UKCA compliance ahead of the end of the transition period on the 1st January 2021