Green surfactants for eco-friendly products

Holiferm is commercialising biosurfactants for use in environmentally friendly home and personal care products

Advanced fermentation technology and process developers

Holiferm is a technology development company that holds proprietary technology developed by the founders at The University of Manchester. The wealth of industrial biotechnology and process engineering experience in our team, combined with our worldwide industrial and academic network, allows us to develop the lowest cost production processes for a range of lipid products our technology can be applied to.

How it’s done

Accelerating the transition

Holiferm is a purpose-led company that aims to accelerate the transition to a circular economy by developing and supplying sustainable, non-fossil based, fermentation-derived ingredients for industrial and consumer products. Holiferm transform existing biosurfactant and lipid production processes by taking traditional and expensive batch fermentation and developing commercially viable, continuous manufacturing processes to deliver green products to the mass market at the correct volume and price point.

Patented integrated gravity separation

Holiferm’s patented integrated gravity separation and fermentation technology is a plug and play system that increases fermentation process productivity by three to four times, reducing production costs by more than 50% and enabling low cost production of biosurfactants: renewable, biodegradable and mild alternatives to the petrochemical derived surfactants used in household cleaning, laundry and personal care products. Holiferm is dedicated to the commercialisation of economic biosurfactant production processes, providing a complete platform technology for production, isolation and purification, enabling significant market disruption and growth.

Holiferm’s Technology

A low cost route to a range of biosurfactants and other lipid molecules

Holiferm’s integrated gravity separation fermentation process provides a low cost route to a range of biosurfactants and other lipid molecules, delivering high productivity fermentation processes for the manufacture of green, biobased and biodegradable molecules.

Integrated gravity separation

Holiferm’s technology and know-how spans the entire process for the production of sophorolipids, from feedstock to downstream processing. Additionally, Holiferm’s knowledge can be applied to develop other fermentation-based production processes which outperform existing processes on a productivity and cost basis. The key reason Holiferm are able to produce sophorolipids at a lower cost point than the state of the art is Holiferm’s superior fermentation technology, combined with knowledge and expertise in downstream processing, which is critical in ensuring sophorolipid product quality and consistency. Holiferm’s sophorolipid production process is based on a natural yeast fermentation, using vegetable oil and glucose as raw materials.

The downstream process is based around phase and gravity separation, with the integrated gravity separation technology developed by Holiferm having been demonstrated at two commercial sites, to pilot scale, achieving performance of double the state of the art for two of the most economically important metrics for sophorolipid production, reaching titers >1000 g/l and productivities >5 g/l/h.

Biosurfactant platform development

Holiferm’s technology has been demonstrated for the production of mannosylerythritol lipids (MEL), rhamnolipids and terpenes by fermentation, dramatically enhancing the titer and productivity, and is applicable to the production of a range of glycolipid biosurfactants. Holiferm has formed a consortium of world leaders in the identification and production of novel biosurfactants, the chemical modification of biosurfactants, and the application of biosurfactants. This enables Holiferm to offer a complete biosurfactant platform solution, producing biosurfactants tailor-made to an application for an interested company, through our manufacturing partner if preferred, and supporting with formulation and application. The use of Holiferm’s technology in biosurfactant production can enable an economically viable production for these molecules, enabling market disruption with low-cost biosurfactants.

Other lipids

Holiferm have demonstrated, through a proof of principle study, that the integrated gravity separation technology can be successfully applied to lipid producing fermentations outside the biosurfactant space.

A number of potential targets have been identified:

Terpenes

Polyol esters of fatty acids

Long chain dicarboxylic acids

Lactones

Hyaluronic acid

Other microbial oils

More information can be found via the link below :

Holiferm’s Products

Biosurfactants from renewable feedstocks via a natural fermentation process

Holiferm produce biosurfactants from renewable feedstocks via a natural fermentation process, using yeast naturally found in honey. Holiferm’s sophorolipids are 100% biodegradable, bio-based surfactants, which are offered in high and low foaming versions.

HoneySurf LF

Created using a yeast naturally found in honey, HoneySurf LF is produced by a natural fermentation process. HoneySurf LF is naturally low foaming (LF) and can used in formulations for a variety of LF applications, from hard surface cleaners to face creams, shampoos and conditioners.

HoneySurf LF is REACH exempt, exhibits an extremely low toxicological profile and can be used for EU ecolabel formulations.

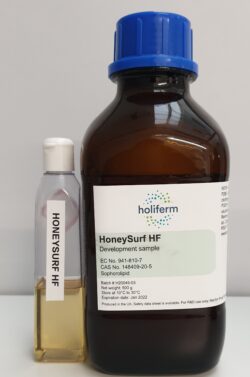

HoneySurf HF

HoneySurf HF is produced by natural fermentation followed by a simple chemical modification step carried out at mild, gentle conditions. HoneySurf HF is high foaming (HF), generating and stabilising foam. A wide range of possible applications exist from car cleaning to manual dishwash.

HoneySurf HF exhibits an extremely low toxicological profile and can be used for EU ecolabel formulations.

Meet the Holiferm Team

COSMOS APPROVED

Holiferm – Bringing biosurfactants to market

Message Holiferm Limited directly.

Richard Lock, Andrew Hardwick